-

Mosaic -

Clear all

Zelligerar Mosaic FAQ

-

How are your zellige mosaics constructed and in what format are they delivered?

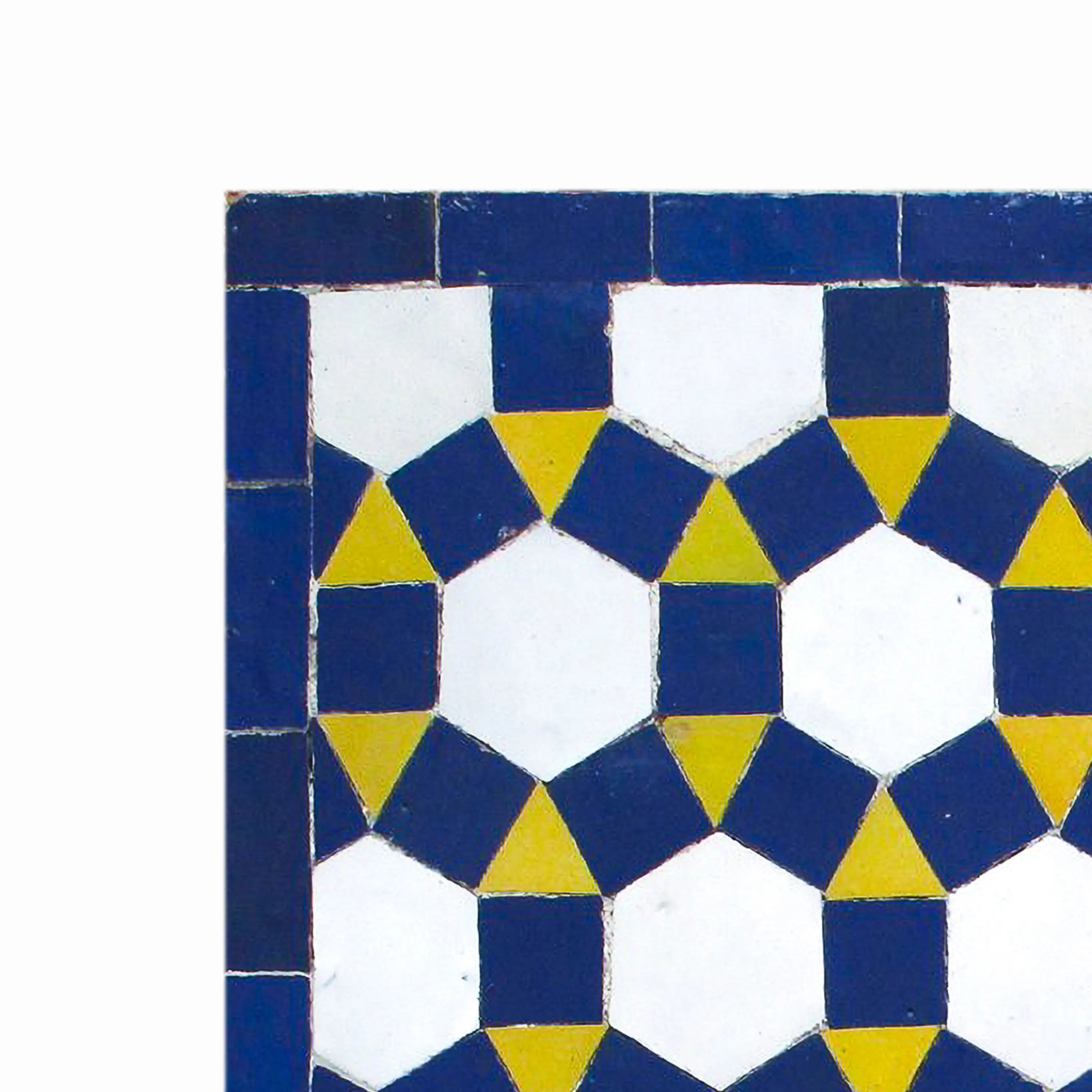

Our mosaics are made from small, hand-chiseled pieces of tile known as tesserae. Master artisans meticulously assemble these individual pieces face-down into an intricate pattern. They are then backed onto interlocking sheets, typically around one square foot, which allows for a much simpler installation process compared to setting each tiny piece by hand on site.

-

With so many small pieces, how is pattern consistency maintained across multiple sheets?

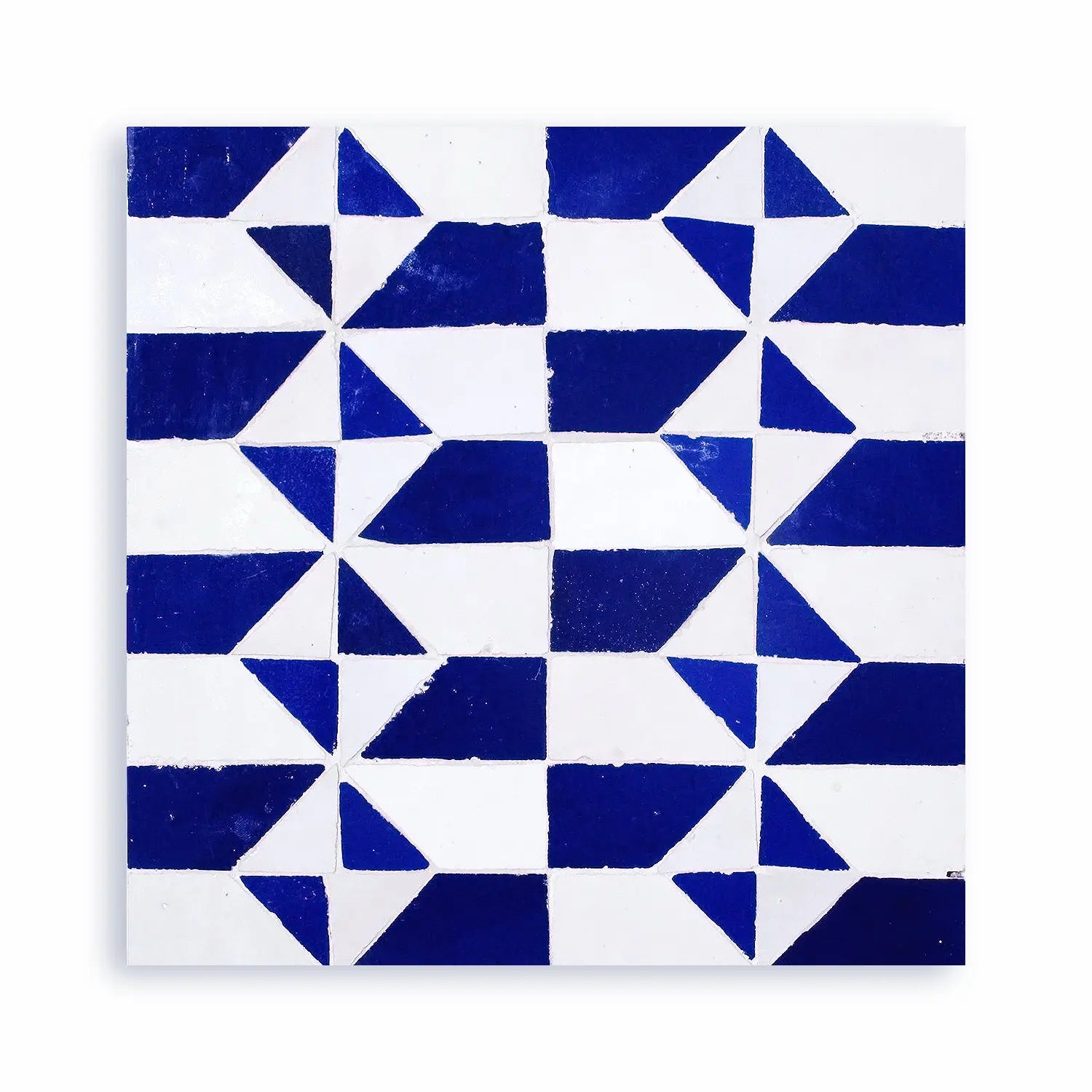

Our artisans, or Maâlems, use time-honored techniques and precise templates to guide the assembly of every mosaic sheet. While each tiny tessera has its own unique character, the overall geometric flow and accuracy of the pattern are expertly maintained from one sheet to the next, ensuring the final installation appears as a single, seamless work of art.

-

Are zellige mosaics suitable for wet areas like shower floors or fountains?

Yes, zellige mosaics have been used in wet environments like Moroccan hammams and fountains for centuries. Their suitability depends entirely on proper installation. A waterproof membrane must be used behind the mosaics, and the final installation must be sealed thoroughly to protect the grout and prevent water from getting behind the tiles.

-

What is the recommended grouting process for these pre-assembled mosaic sheets?

Grouting mosaic sheets requires care to ensure all the small crevices are filled. We recommend using a non-sanded grout to avoid scratching the tile glaze. The grout should be firmly applied with a float, approaching the sheet from multiple angles to fill every joint. After a brief setup time, the excess should be carefully wiped away with a damp sponge.

-

Is it possible to order a custom-designed mosaic pattern or change a pattern's scale?

Absolutely. We specialize in bringing custom mosaic visions to life from architectural drawings or inspirational images. Furthermore, we can adjust the scale of any of our existing catalog patterns, making the design elements larger or smaller to perfectly suit the proportions of your project. This is a collaborative design process we undertake with our clients.

-

Why are the production lead times for mosaics longer than for single zellige tiles?

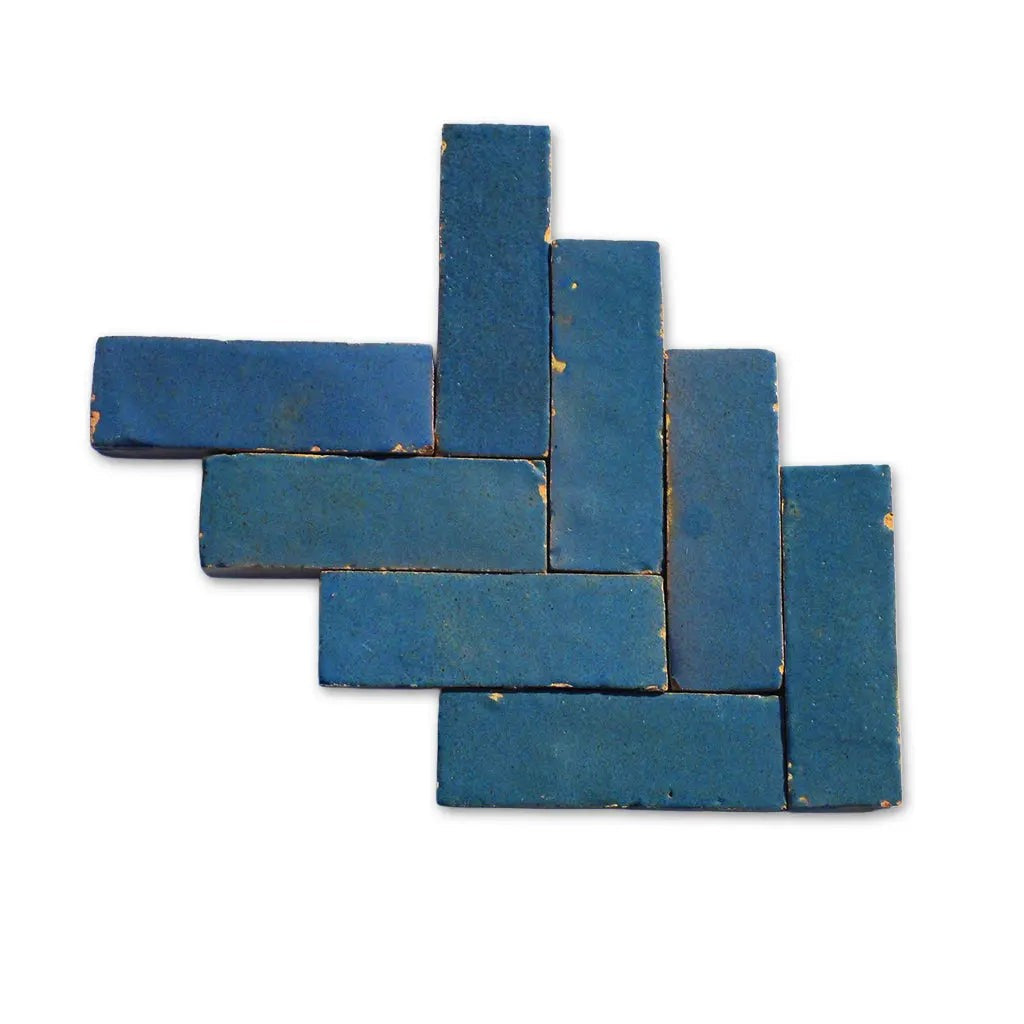

The creation of a zellige mosaic is a multi-stage, labor-intensive art form. First, larger tiles are glazed and fired, then each small tessera is hand-chiseled from those tiles. Finally, an artisan hand-sets every one of those pieces into the final pattern. This intricate, two-part craft is performed entirely by hand and naturally requires a more extensive production timeline.

-

What is the process for repairing a mosaic sheet if a piece is damaged?

To account for potential damage during shipping or installation, we always include extra loose tesserae with your order. If a piece needs to be replaced, the damaged one can be carefully chipped out. The replacement piece is then set in its place with a small amount of tile adhesive before the final grouting of the entire surface.

-

What is the design and approval process for a custom mosaic order?

For any custom mosaic project, we begin with your design concept and color palette. Our team will then produce a digital rendering or a physical sample for your final approval. Once you have formally signed off on all design elements, including the pattern, scale, and color selection, we will begin the full production of your order.